Located on National Highway-6, only 1 KM from the Uluberia Railway Station, and 44 KM from the city of Kolkata giving it excellent road, railway, and port connectivity.

MT per hour liquid metal handling capacity, with 1 MT Inductotherm Induction Furnace installed in phase 1 of the project.

DISA Vertical, high-pressure, flaskless molding line of 650x535 mold box size with a speed of 150 molds per hour. This is a fully automated system and gives us an edge in producing small castings at scale.

Resin Sand, and Cold-Box Shell Core automatic core shooters to ensure maximum flexibility for our products. Stress is placed on high quality of sand for cores and molds to ensure good finishing.

Fully Automatic, High Quality 40 MT capacity plant. 20 MT will be utilized in phase 1 of the project.

Automatic Tumble Blast facility for proper cleaning with automatic Degating System planned expansion.

Fully equipped laboratory, including spectrometer, tensile, hardness, and other testing machines.

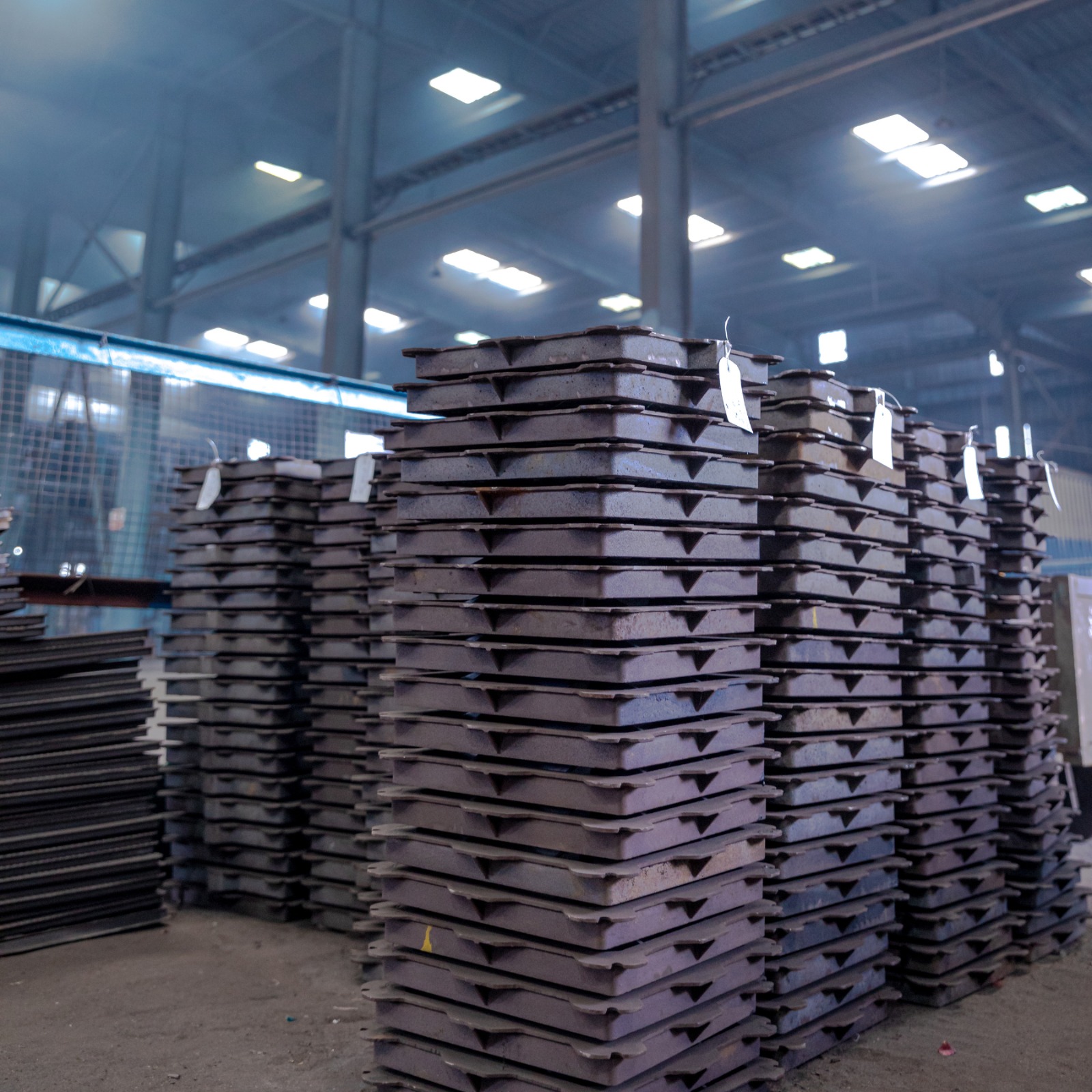

We use metal patterns and have full storage ability.

We have a grinding bank , lathers, and drilling machines for proper finishing of the product.Primer and epoxy painting facility is available as per customer requirements.

We use premium quality of palleting for our products to avoid any damage while shipment.

We use various types of quality paint, such as Bitumen, Alkyd resin, and Epoxy, depending on the requirement.

We ensures seamless and efficient dispatch solutions, delivering reliably through optimized sea freight logistics.